Product Description

BSD Series Stepped Cold Rolled Ball Screw (C5/Ct7)

| Table of Shaft dia. and Lead combination for Rolled Ball Screw | ||||||||||||||||

| Lead (mm) | ||||||||||||||||

| 0.5 | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 20 | 30 | ||

| Shaft dia (mm) | 4 | / | / | |||||||||||||

| 5 | / | |||||||||||||||

| 6 | / | / | / | / | ||||||||||||

| 8 | / | / | / | / | / | / | / | |||||||||

| 10 | / | / | / | / | / | / | / | / | / | |||||||

| 12 | / | / | ||||||||||||||

| 13 | / | / | / | |||||||||||||

| 14 | / | / | ||||||||||||||

| 15 | / | / | / | |||||||||||||

| 16 | ||||||||||||||||

Accuracy Class & Axial Clearance

Accuracy grade of BSD series(standard stepped cold rolled ball screw) are based on C5 and Ct7(JIS B 1192-3). According to accuracy grade, Axial play 0.005(Preload :C5) and 0.02mm or less(Ct7).

Material & Surface Hardness

BSD series (Standard Stepped cold rolled ball screw) of screw shaft screw material S55C (induction hardening), nut material SCM415H (carburizing and hardening), the surface hardness of the ball screw part is HRC58 or higher.

Shaft End Shape

The shape of the shaft end of the BSD series (stepped cold rolled ball screw) has been standardized.

Application:

1. Medical industry

2.Lithium battery industry

3.Solar photovoltaic industry

4. Semi conductor Industry

5. General industry machinery

6. Machine tool

7. Parking system

8. High-speed rail and aviation transportation equipment

9. 3C industry etc

Technical Drawing

Specification List

FACTORY DETAILED PROCESSING PHOTOS

HIGH QUALITY CONTROL SYSTEM

FAQ

1. Why choose CHINAMFG China?

Over the past 14 years, CHINAMFG has always insisted that “products and services” start from Japanese industry standards,taking ZheJiang standards as the bottom line, actively invest in the development of new transmission components and self-experiment and test. With the service tenet of “exceeding customer expectations”, establish a “trusted” partnership.

2. What is your main products ?

We are a leading manufacturer and distributor of linear motion components in China. Especially miniature size of Ball Screws and Linear Actuators and linear motion guideways. Our brand “KGG” stands for ” Know-how,” ” Great Quality,” and ” Good value” and our factory is located in the most advanced city in China: ZheJiang with the best equipment and sophisticated technology, completely strict quality control system. Our aim is to supply world leader class linear motion components but with most reasonable price in the world.

3. How to Custom-made (OEM/ODM)?

If you have a product drawing or a sample, please send to us, and we can custom-made the as your required. We will also provide our professional advices of the products to make the design to be more realized & maximize the performance.

4. When can I get the quotation?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

5. How can I get a sample to check the quality?

After confirmation of our quoted price, you can place the sample order. The sample will be started after you CHINAMFG back our detailed technical file.

6. What’s your payment terms?

Our payment terms is 30% deposit,balance 70% before shipment. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision: | C5/C7 |

|---|---|

| Screw Diameter: | 14mm |

| Flange: | With Flange |

| Nut Number: | Single |

| Rows Number: | 3-Row |

| Nut Type: | Stepped Type |

| Customization: |

Available

|

|

|---|

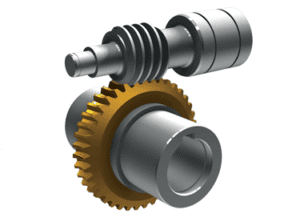

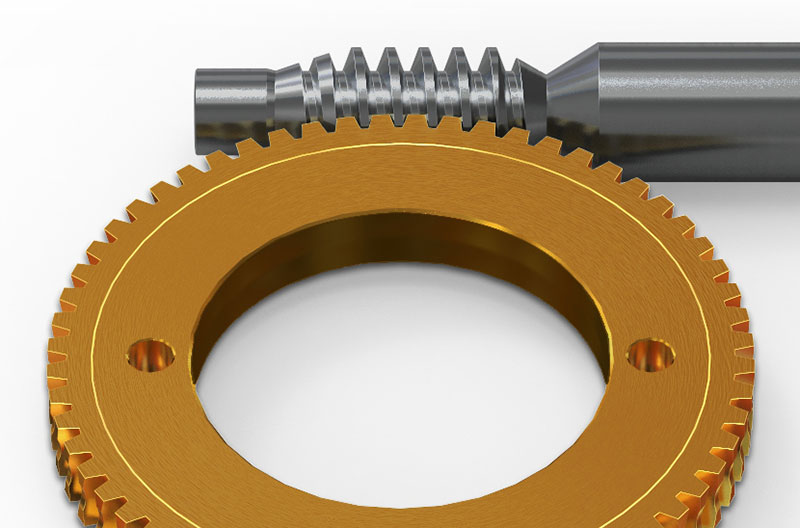

Can worm screws be used for high torque applications?

Yes, worm screws can be used for high torque applications. The design of a worm screw mechanism allows for efficient torque transmission and multiplication, making it suitable for applications that require high torque output. Here are some key points to consider regarding the use of worm screws in high torque applications:

- Gear Reduction: One of the primary advantages of a worm screw mechanism is its ability to provide a significant gear reduction in a single stage. The helical threads of the worm screw and the meshing teeth of the worm wheel create a high reduction ratio, which results in a lower output speed and higher output torque. This gear reduction capability allows worm screws to generate and transmit substantial torque, making them well-suited for high torque applications.

- Efficiency: While worm screws can provide high torque output, it’s important to consider the mechanical efficiency of the system. The efficiency of a worm screw mechanism can vary depending on factors such as the materials used, lubrication, and design parameters. However, compared to other gear systems, worm screw mechanisms tend to have lower efficiency due to inherent friction between the threads and teeth. It’s crucial to ensure that the efficiency of the worm screw mechanism meets the requirements of the specific high torque application.

- Load Holding: Another advantage of worm screws is their self-locking property. Due to the helical shape of the threads, the worm screw has a wedging effect on the worm wheel, which provides resistance against backward rotation. This self-locking feature allows worm screws to hold loads in a fixed position without the need for additional braking mechanisms. In high torque applications where load holding is required, worm screws can provide reliable and secure positioning.

- Material Selection: The materials used for the worm screw and worm wheel should be carefully selected to withstand high torque loads. Both components should have sufficient strength and wear resistance to handle the transmitted torque without deformation or premature failure. Depending on the specific application requirements, materials such as hardened steel, bronze, or other alloys may be chosen to ensure the durability and performance of the worm screw assembly.

- Lubrication and Maintenance: Proper lubrication is crucial for the smooth operation and longevity of a worm screw mechanism, especially in high torque applications. Adequate lubrication helps reduce friction, wear, and heat generation between the contacting surfaces, ensuring efficient torque transfer. Regular maintenance, including monitoring lubricant levels and replenishing or replacing the lubricant as needed, is essential to maintain optimal performance and prevent premature wear or failure.

Overall, worm screws can be effectively used in high torque applications, thanks to their gear reduction capabilities, load-holding properties, and efficient torque transmission. However, it’s important to carefully consider factors such as mechanical efficiency, material selection, lubrication, and maintenance to ensure that the worm screw mechanism can meet the specific requirements and demands of the high torque application.

How do you troubleshoot problems in a worm screw gear system?

Troubleshooting problems in a worm screw gear system requires a systematic approach to identify and resolve issues effectively. Here are the steps involved in troubleshooting problems in a worm screw gear system:

- Identify the Symptoms: Start by identifying the specific symptoms or issues that indicate a problem in the worm screw gear system. This can include abnormal noise, reduced performance, increased backlash, erratic motion, or any other noticeable deviations from normal operation. Gather as much information as possible about the symptoms to help narrow down the potential causes.

- Inspect and Clean: Conduct a visual inspection of the worm screw gear system to check for any obvious signs of wear, damage, misalignment, or contamination. Inspect the threads of the worm screw and the teeth of the worm wheel for signs of pitting, scoring, or other surface irregularities. Clean the components if necessary to remove any debris or contaminants that may be affecting the system’s performance.

- Check Lubrication: Review the lubrication of the worm screw gear system. Ensure that the system is adequately lubricated with the recommended lubricant and that the lubricant is in good condition. Insufficient or degraded lubrication can result in increased friction, wear, and inefficiencies. Replenish or replace the lubricant as needed following the manufacturer’s guidelines.

- Inspect Alignment: Verify the alignment of the worm screw and the worm wheel. Misalignment can cause issues such as increased friction, wear, and reduced efficiency. Check for any signs of misalignment and make adjustments as necessary to ensure proper alignment of the components. This may involve repositioning or realigning the system or addressing any underlying factors contributing to the misalignment.

- Measure Backlash: Measure the amount of backlash present in the system. Excessive backlash can lead to reduced accuracy, loss of motion control, and diminished performance. Use appropriate measuring tools, such as dial indicators, to quantify the amount of backlash. If the backlash exceeds acceptable limits, consider adjusting the system to minimize or eliminate the excessive clearance between the threads and the teeth.

- Check Load and Overloading: Evaluate the loads applied to the worm screw gear system and compare them to the system’s design limits. Overloading the system can lead to accelerated wear, tooth breakage, or component deformation. If the loads exceed the system’s capacity, consider redistributing the load, upgrading the components, or redesigning the system to handle the required loads appropriately.

- Address Specific Issues: Based on the symptoms and findings from the inspection and measurements, address any specific issues identified in the worm screw gear system. This may involve repairing or replacing worn or damaged components, adjusting clearances, realigning the system, improving lubrication, or addressing any other factors contributing to the problems observed.

- Test and Monitor: After addressing the identified issues, test the worm screw gear system to verify that the problems have been resolved. Monitor the system’s performance during operation to ensure that the symptoms have been effectively mitigated. Pay attention to any new or recurring issues that may require further investigation or adjustments.

It is important to note that troubleshooting problems in a worm screw gear system may require expertise and experience. If you encounter complex or persistent issues that you are unable to resolve, it is recommended to seek assistance from qualified technicians or professionals with knowledge in mechanical power transmission systems.

What are the typical applications of worm screws in machinery?

Worm screws, also known as worm gears or worm gear screws, have a wide range of applications in machinery where motion transmission and torque multiplication are required. Their unique characteristics make them suitable for various industries and applications. Here are some typical applications of worm screws in machinery:

- Conveyor Systems: Worm screws are commonly used in conveyor systems to control the movement of materials. They provide precise speed reduction and torque multiplication, allowing for efficient transportation of goods in industries such as manufacturing, packaging, and logistics.

- Lifting Mechanisms: Worm screws are extensively used in lifting mechanisms, such as screw jacks or worm gear lifts. They provide reliable and controlled vertical motion for lifting heavy loads in applications like automotive service garages, construction sites, and material handling equipment.

- Winches and Hoists: Worm screws are employed in winches and hoists to provide high torque and controlled lifting or pulling operations. They are commonly used in applications such as cranes, marine equipment, elevators, and stage rigging.

- Rotary Actuators: Worm screws are utilized in rotary actuators to convert the input rotary motion into a controlled rotary output motion. This makes them suitable for applications like valve actuators, positioning systems, and robotic joints.

- Automotive Applications: Worm screws find use in automotive applications, particularly in steering systems. They are employed in steering gearboxes to convert the rotary motion from the steering wheel into the lateral motion required for steering the vehicle.

- Machine Tools: Worm screws are used in machine tools, such as milling machines, lathes, and drill presses, to control various linear and rotary movements. They provide precise positioning and motion control for cutting, shaping, and drilling operations.

- Printing and Packaging Machinery: Worm screws are employed in printing and packaging machinery to control the movement of printing heads, cutting blades, and packaging components. They ensure accurate and synchronized motion for high-quality printing and packaging processes.

- Robotics: Worm screws are utilized in robotics for precise and controlled motion in robotic arms, grippers, and other robotic mechanisms. They enable accurate positioning and smooth motion control in industrial automation and robotic applications.

These are just a few examples of the typical applications of worm screws in machinery. Their ability to provide high gear reduction ratios, precise motion control, and self-locking characteristics make them suitable for a wide range of industries, including manufacturing, construction, automotive, robotics, and many others where efficient power transmission and controlled motion are essential.

editor by CX 2024-03-03